Technology – “ ECOBOI ”

Working Principle of “ ECOBOI ”: ECO + BOI

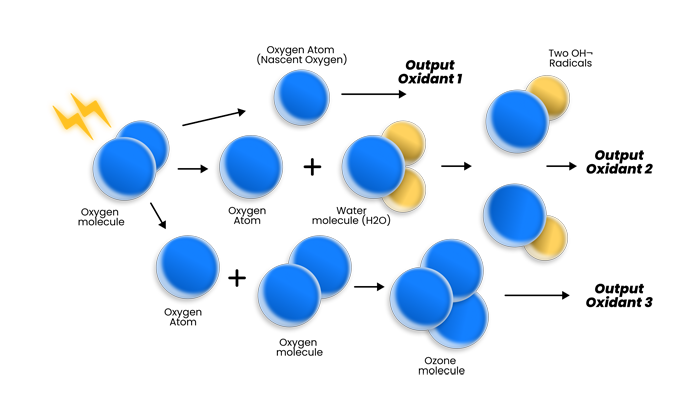

In mother nature, when lightning strikes it breaks the oxygen molecule to produce different derivatives of Oxygen to purify air, water & land surfaces. These are environmental friendly nascent oxygen, Ozone, Hydroxyl radicals, positive ions & negative ions. ECO stands for “Electro Chemical Oxidation” which uses high frequency, high voltage electronic driver & ECO reactor. Ambient air or pure oxygen is fed to ECO reactor by air pump from inlet & inside ECO reactor, electrically oxygen molecule is broken. This produces nascent oxygen atom, which is a natural oxidising agent. The nascent oxygen further combines with moisture in air to produce OH – radicals.

Some part of oxygen atom combines with oxygen molecule to produce ozone. BOI stands for “Bipolar Oxygen Ionisation”, which makes molecules to release or gain electrons, making them positive ions or negative ions.

These ions are the carrier of ECO, extending its reach & at the same neutralising the charge on colloidal suspended particles in occupied air. By neutralising the charge the colloidal particles now agglomerate & either settle to ground or gets trapped in air filters. Now with this, not only the suspended particles but also attached bacteria, viruses, molds & spores also gets significantly reduced. Also these – ve & + ve ions are ready to exchange electrons by donating or by accepting from the atmospheric chemical pollutants.

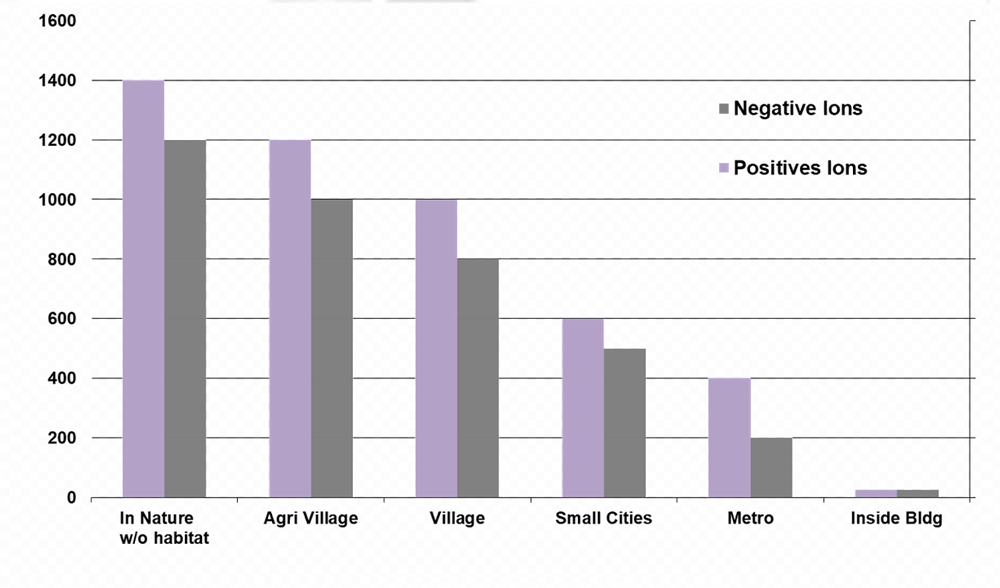

Distribution of Negative & Positive ions:

In nature both negative & positive ions are present naturally, purifying the atmosphere. As population increases, the pollution also increases which drastically reduces the density of these ions. Inside modern day buildings, offices, schools, hospitals, hotels, banks the ions density is too low. This is mainly due to the available ions in cities are extremely low due to city pollutions, dense population & lack of natural resources. Also, generation or source of these energy ions are missing inside modern day buildings.

Importance of Negative & Positive ions:

These negative & positive ions are not only purifying atmosphere but are the root cause of energy & freshness. They also fight against colloidal particles, chemicals & microorganisms, protecting building occupants. Many building related illness, commonly known as “Sick Building Syndromes” (SBS) like sinus, headache, fatigue, allergies, eye allergies, itching etc. These negative & positive ions in indoor spaces can enhance “Indoor Air Quality” IAQ & reduce sick building syndromes. This results in less absenteeism & enhanced performance.

Indoor Air Quality (IAQ) significantly depends on the selection, reach & depth of the treatment technology & methodology.

Spectrum Coverage – Technology Selection:

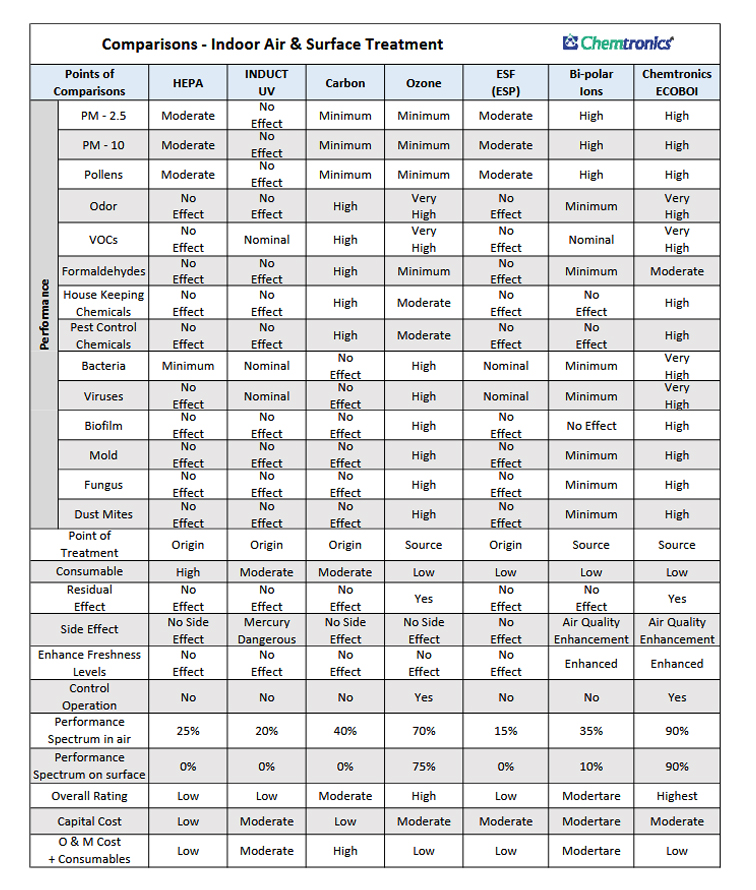

First and most crucial is the selection of the right treatment technology for Indoor air pollutants & contaminants. In the below spectrum coverge web, it is clear that different treatment technology has different effectiveness on possible pollutants & contaminants. Indoor air pollutants are broadly classified as physical, biological & chemical. To neutralize them, each needs a different treatment or combination of treatments. Select one the most suitable & effective for the pollution you wish to address. Select one has the maximum spectrum coverage over diversified pollutants, maximum penetration reach and highest depth of strength & power.

High Efficiency Particulate Air (HEPA) Filter:

Colloidal particles like fine dust, pollen etc. are extremely small classified as PM 1, PM 2.5 & PM 10 as per their size in microns (1 micron = 1/1,000 mm). These particles possess positive charge on them, which keep them suspended in the air by continuously repelling each other. The High Efficiency Particulate Air (HEPA) filter can trap particles as small as 0.3 micron. These filters have high replacement frequency & are only applicable in central HVAC system or stand alone filters. For them to be effective air with colloidal particles should flow through them. HEPA filters are mechanical physical filters having minimal to nil effectiveness on biological pollutants, since all viruses are less than 0.3 micron and chemical pollutants can simply pass through them with air. HEPA filters are completely ineffective on dust particles which are settled on surfaces, floor, carpets, false ceilings, furniture & electronic equipment.

Ultra-Violet (UV) Radiation :

An ultraviolet germicidal UV-C light radiation of wavelength 253.7 has excellent performance on biological pollutants. But the UV radiation is extremely dangerous for human eyes & skin, if exposed. Even a short time exposure can cause severe conjunctivitis, psoriasis & skin cancer, so they have to be kept covered / enclosed. To treat biological contaminations air has to pass through these lights at very slow velocities to have a sufficient contact time for neutralization. Normally, air which is flowing in centralized air handling units (AHU) and ducts, can only offer 0.02 – 0.05 second of contact time. For effective CT value (concentration X time) more no. of lamps are needed to increase the concentration to compensate for the short contact time. Also, this germicidal light cannot reach places where the bacteria, viruses, mold, fungus, dust mites can hide & multiply. Its lethal performance is practically ineffective at the point of germ source. Again UV lamps are made up of a thin long glass tubes filled with Mercury, which is highly dangerous & needs careful handling.

Activated Carbon Filter (ACF):

Activated carbon filters of 800 – 1,000 iodine value are extremely effective in adsorbing most of the chemical pollutants in the air. But, for them to be effective air has to be continuously passed through them. So they can be either stand alone or can be integrated with the centralized AHU system. The major drawback is that over time, they become a breeding ground for bacteria & viruses. The replacement frequency is high with recurring cost. They are absolutely ineffective on particulate matter & biological pollutants. Also carbon filter can not adsorb chemical pollutants from the source like furniture, paint, pest control & housekeeping chemical pollutants.

Bipolar Oxygen Ions (BOI) :

When Oxygen orbital is broken electrically, millions of positive protons & negative electrons are released in indoor air. This gives a charge to suspended colloidal particulate matter (PM) making them agglomerate & settle on the ground. In cases of AHU & ductwork, their bigger size effectively traps them in mechanical filters. Any other chemical and biological pollutant associated with particulate matter also settles down on ground, thereby offering limited efficiency. This can be strategically installed in the AHU ductwork and in local area. BOI has very negligible effect on chemical & biological pollutants.

Electro Chemical Oxidation (ECO):

An advanced version of air treatment uses oxidation technology to oxidize all biological & most of chemical pollutants with high efficiency. The technology uses electricity to produce oxidant on site. This oxidant works on point of source of the pollutant. It reaches every place where any virus & bacteria can hide.

Chemtronics Innovative ECO + BOI:

Chemtronics R & D team has developed unique blend of ECO + BOI to cover the most of the pollutants which can be physical, biological and chemical. In this integration, oxidation is extended to produce advance oxidation to offer high degree of spectrum coverage with better reach & depth of the treatment for optimum performance. The greatest advantage is the disinfectant does not need any consumable, as it is produced from ambient air, using electricity. The treatment is at the point of source, where air can reach. Low operation & maintenance cost without any consumables.

Below, different indoor air treatments are compared for their performance, reach & depth of treatment.