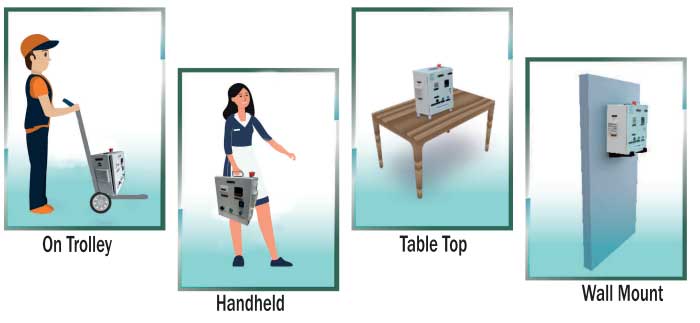

Portable air ozone generator produces ozone gas from ambient air. Advantage of producing ozone from air is that it does not require extra equipment to produce oxygen & the concentration of ozone is low but sufficiently adequate. This makes it very safe during its use as an odor eliminator, disinfection, enhances indoor air quality etc. their Standard capacities are 250 mg/hr, 500mg/hr. Portable air ozone generator can be kept on a trolley to be moved from one place to other. It has a handle, thus it can be carried in by hand. At the same time, if required a wall can be wall mounted or it can be kept on the table top.

Features :

Heavy duty Commercial & Industrial grade

Easy Operation – Plug & Play

Continuous Timer Mode | One Time Mode

Built In Feed Air Pump

Flexible Ozone Gas Tubing

Portable – Light Weight

Ozone Generation From Ambient Air

Emergency stop button.

Air ozone generator application :

Major applications of air ozone generators are to reduce

practically all kinds odor and disinfect air by destroying all

airborne bacteria, viruses, mold, fungi, spores etc. Ozone is a very

strong oxidizing agent can quickly reduce air contaminations and

pollution. Following are few of its application areas:

Air disinfection

Air Odor Control

VOC reduction

Reduce Sick Building Syndromes

Enhance Indoor Air Quality

Smoking lounges

Fire/Burning odor reduction

Sewage & Garbage odor reduction

OT & ICU disinfection

Air Fumigation

Clean room applications

Production, Packing & Storages

Cold rooms | cold storages.

Diversified Industrial Use:

Food Processing

Bakery & Confectioneries

Dairy

Wineries

Horticulture

Process | Packing

Storage | Cold Storages

R & D Labs

Pharmaceutical

Medical & Health Care

Hotels | Resorts | Hospitality

Smoking Lounges

House Keeping | Tank Cleaning

Bar | Pubs | Restaurants | Clubs

Car & Bus coaches Cleaning

AHU Duct Cleaning & Disinfecting

Godown | Store Rooms

Clean Rooms

Corporate Offices

Schools | Collages

Shopping Malls

Theaters

Gym | Sports Clubs

Mosque | Temples | Churches

Mode of Operation:

As per different operation conditions & requirements, air ozone

generators can be used in followings operating modes:

One time Timer - In is mode when user presses

START button, air ozone generator starts releasing ozone in air for

preset time. After the end of this time ozone generator goes in to

standby condition until again start button is pressed.

Continuous Timer – Under this mode after pressing

START button, ozone generator starts generating ozone for preset

time, after the lapse of this time, it goes in for standby (off)

condition. Once off time is over it starts again and cycle repeats.

Continuous ON – In this mode air ozone generator

remains continuously on till the mains power is on.

| Series | PORTO – 50 I 100 |

| Treatment Methodology | Penetrate & Treat |

| Technology | Electro Chemical Oxidation (ECO) + Bipolar Oxygen Ionization (BOI) |

| Make | Chemtronics® |

| Made in | India |

| Feed Gas | Dry filtered ambient air |

| Oxidation Reactor | Concentric Cylindrical |

| Dielectric | Precision Ceramic |

| Reactor Cooling | Forced Air Cooled |

| Electrode Cooling | External electrodes with integrated aluminum heatsink. |

| Minimum Reactor life | 10,000 Hrs |

| Reactor Cleaning frequency | Every - 5,000 Hrs |

| Oxidant Concentration | 1,000 - 1,200 mg/m3 |

| BOI Riders | 10 - 20 MPCC @ Source |

| Mounting/Installation | Portable/Table Top/Floor |

| LED Indicators | ECOBOI + BOOSTER + POWER ON |

| Service Indicator | Non resettable hour meter – PLC Based |

| Enclosure MOC | Standard - MS Powder coated | Optional – SS – 304 |

| Enclosure Thickness | Minimum 1.2 mm |

| Enclosure/ Surface Finish | Machine polish with Structure Powder coating |

| Injection Connection | Anti-oxidant / Polypropylene / PTFE |

| Line Protection | Input Surge & spike protection |

| Line Filter | EMI/RFI Filter |

| Onboard Protection | Overheat; Over Current; Over Voltage |

| Safety Compliance | OSHA, USEPA, NIOSH, WHO, USEPA |

| Line Voltage | 230 V AC ; I phase ; 50 Hz |

| Power Consumption | 100 W |

| Dimension (H x W x D) mm | 500 x 400 x 210 |

| Net Weight (kg) | 15 Kg |

| Certification | CE | ISO 9001 - 2015 |

| Series | Capacity (mg/m3) | No. of Modules |

Dimension (WXLXH) |

Net Weight (kg) |

Power [W] |

| PORTO -50 | 1,000 -1,200 | 1 | 300 X 250 X 155 | 7.0 | 100.0 |

| PORTO -100 | 1,000 -1,200 | 2 | 400 X 300 X 210 | 10.0 | 145.0 |

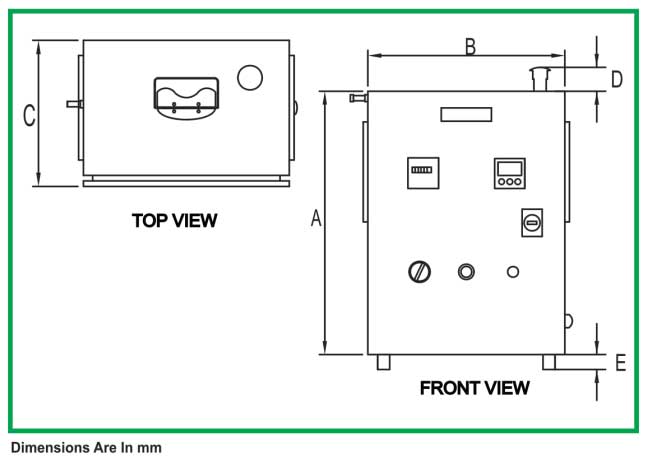

| Model No. | A | B | C | D | E |

| PORTO -50 | 300 | 250 | 155 | 35 | 25 |

| PORTO -100 | 400 | 300 | 210 | 35 | 25 |