Advanced Oxidation Process

Advance Oxidation Process, commonly known as AOP is used for industrial wastewater treatment and zero liquid discharge is to be achieved. When wastewater is having a chemicals

of complex molecular bonds, color, micro-pollutants, high COD, hormones, etc. where conventional effluent treatment is difficult to treat. In Advanced Oxidation Process high

concentration Ozone is used with Hydrogen Peroxide (H2O2) or Ultra-Violet to generate Hydroxyl radicals.

Three ways to produce AOP in wastewater :

- Ozone + H2O2

- Ozone + UV

- Ozone + H2O2 + UV

Only Ozone at time becomes performance/oxidation saturated, where increases in Ozone Dose cannot further reduce/oxidize pollutant.

Below one can notice the spectrum coverage of different technologies on various pollutants.

| Compound |

Electrochemical Oxidation

Potential [V] |

| F |

3.06 |

| OH |

2.80 |

| O |

2.42 |

| O3 |

2.08 |

| H2 O2 |

1.78 |

| HOCl |

1.49 |

| CLO2 |

1.27 |

| O2 |

1.23 |

Why AOP for Industrial Wastewater Treatment:

Sludge Reduction

Reduce the Chemical Usage

Enhance Biological Process

Reduce Foot Print

Reduce Process Time

Reduce Wastewater Treatment Cost

Application of AOP Process

AOP for Waste water Treatment.

Advance Oxidation Process is highly recommended for breaking down complex molecular bonds in the wastewater generated by textile industries, dye industries, pharmaceutical industries, chemical industries, paint industries and treat the left over

bacteria’s from the secondary stage so they can be nullified leading to the decrease in COD and BOD levels in the waste water.

AOP for Color Reduction

When AOP is used in the primary stage, it can enhance the Physico-chemical process in reducing the color from the wastewater. The AOP can break the complex molecular

bonds of the color forming dyes and coagulation and flocculation can significantly controls the color from the wastewater.

Zero Liquide Discharge

Now a days, many industries prefer to go with zero liquid discharge philosophy. In most of the industrial waste water treatment it is observed that the COD of the condensed

water from Multi Effect Evaporator is also high. This high COD water cannot be discharged or reused even using reversed osmosis water treatment plant. In this case AOP becomes very effective in reducing final COD.

AOP for Raw Water Treatment

The source of raw water for Industries is the river passing by the factory. Since this river caters to a wide range of Industries & factories along its bank there is a lot of

contamination disposed in this river as waste by other industries.When this river water is supposed to be used as a raw water for the various application in the factory such as drinking, production, process, make up water and many more, it

has toxics and micro-organisms with other Organic compounds. These impurities and infection in the water is not easy for the conventional methods to eradicate easily, they need something which is stronger and powerful such as AOP to react with the micro-organisms and organics. Ozone AOP is also a method in which more oxidants are combined with ozone to make

hydroxyl radicals. These OH radicals are much stronger than ozone alone and once engineered properly in the whole plant it can give better results than existing conventional methods.

AOP for Pharmaceutical Water Treatment

As we know there are new generation of medicines made by pharmaceutical industry which take care of the uprising infections that are not conventional like fever & flu.

When these medicines are produced the raw water needs to be completely disinfected without any scope of regrowth of these micro-organisms. To do so AOP in pharmaceutical industry is widely accepted for raw water as well as wastewater

treatment.

AOP for COD reduction

Advance oxidation procedure is the engineering required to blend two oxidants who have very high oxidation potential individually and when combined can be of much greater potential. When AOP is used in waste water treatment before the water is discharged it rapidly helps in increasing the COD demand in the waste water of any industry. This COD reduction eventually helps in maintaining the ecology of the river in which this waste water is disposed.

AOP for BOD reduction

AOP is extremely effective on high concentration of BOD. AOP is used in the primary stage of the wastewater treatment scheme.

Advance Oxidation Process (AOP) for STP :

Due to extensive use of personal care products (PCPs) & non-biodegradable biocides,endocrine disrupting Chemicals (EDCs), pharmaceutical products & other emerging contamination, domestic waste water becomes more complex & challenging in treating with conventional techniques. At the same time current

& future regulation demands for better quality of recycled waste water for reuse.

The current conventional biological or membrane base [MBR] domestic waste water treatment cannot cope up with this demand of emerging contamination. This results in drop in efficiency

& increase in indicative COD & BOD in waste water units.

To take care of these conditions one requires highest degree of oxidation potentials, 2.80 mV of hydroxyl radicals (OH), which is more than any one individual form. Advance oxidation is the best option so called “Best Available Technology” (BAT).

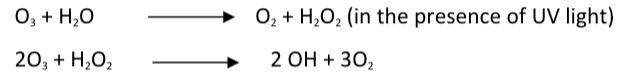

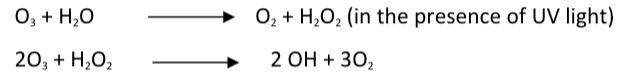

Advance oxidation process is an extended treatment of Ozonation, where Ozone & 253.7 nm wavelength of UV radiation creates hydroxyl radicals to optimize the capital & operational cost. It is a smart way to use AOP with moderate dose of Ozone rather

than using high dose on only ozone giving saturated result. In this UV + Ozone process,photons in the UV light convert Ozone in the presence of water to oxygen & peroxide.

The peroxide then reacts with the Ozone to form hydroxyl radical, please check below reaction.

Technological Spectrum coverage:- UV | Chlorine | Ozone | AOP

• AOP is extremely quick in oxidation.

• Primary degradation- structural change in the parent compound.

• Accepted degradation – structural change in the parent compound to the extent that toxicity in reduced / eliminated.

.