Commercial Kitchen ventilation system serves to dissipate heat, oil, grease, smoke, toxic gases & odour to provide fresh environment in the kitchen. It is important & in some cases mandatory to treat these exhaust pollutants before they are released to atmosphere. In the process of kitchen ventilation, oil & grease gets deposited in inner surface of the exhaust ducts, which is the greatest threat to commercial kitchen. Grease at higher temperature is highly flammable, burning at high temperature can lead to a uncontrollable fire, difficult to control & can eventually spread very fast.

Solution

Chemtronics has developed a technique by which kitchen exhaust pollutants, toxic gases, oil, grease & odor can all be easily & comprehensively treated with “ECOBOI” technology.

How it Works :

Kitchen hood extracts all heat, smoke, oil, grease, odor, VOCs & through ductwork & suction fan throws out of the building. Strategically, ECOBOI generator is installed in false celling & an oxidant is conveyed to exhaust duct using special flexible ¼” tubing. High concentration oxidants from ECOBOI gets blended in exhaust air & oxidizes oil & grease aerosols in to moisture, CO2 & fine dust & goes out of the kitchen duct. This on the way out oxidizes other VOCs, toxic fumes & odor withing 4 to 5 seconds. The operation of the unit is automatic & takes signal from exhaust fan, such that it starts automatically when fan starts & goes in standby when air flow is stopped.

Applications:

Commercial, institutional & residential kitchens were long ducts are involved for exhaust need safety & exhaust air treatment. These are :

Small & big restaurants kitchen, hotels kitchen, hospital kitchen, food court in mall, corporate office kitchen, kitchens of school & collages, kitchen of clubs, sports club kitchen, stadium kitchen, army kitchens, services staff kitchen, temple kitchens, packed & processed food manufacturing.

There are diversified technologies available as a solution. Below table compares different commonly applied techniques in terms of their advantages & disadvantages.

With the installation of ECOBOI generator one can eliminate the use of electronic filters & Electro Static Precipitator (ESP). But in case of less duct length & lots of smoke, there may be a requirement of installing ESP & ECOBOI together. With both ESP & ECOBOI, design engineer can lower the capacity of both to address the exhaust pollutant at the same time oxidizing greasy duct work. As per site conditions & limitations, experience design consultants selects the one which is technically most optimum & effective, at the same time economically viable. Many time mix of ESP & ECOBOI gives better capital & operational cost benefit. Below are the few generally designed options recommended by us from our past installed site data:

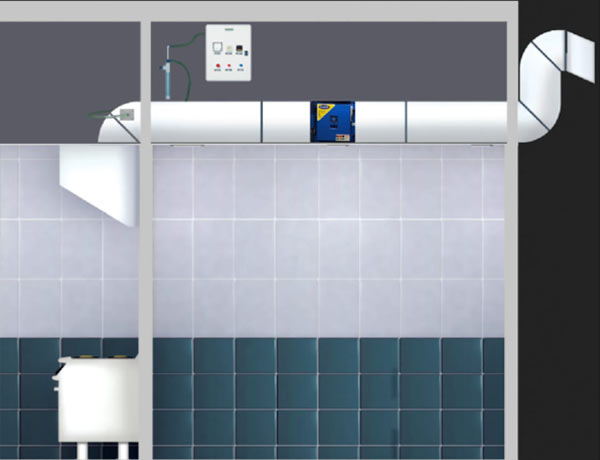

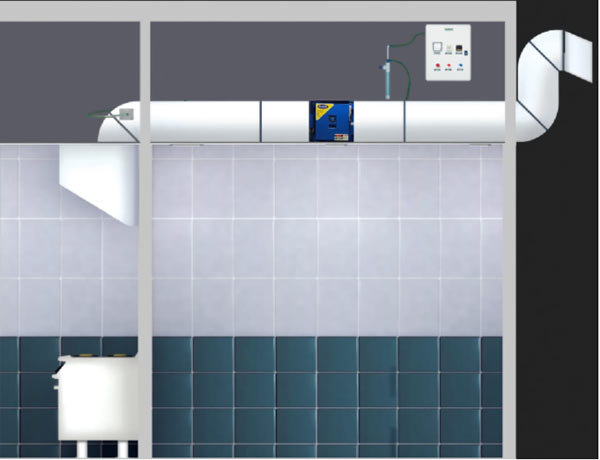

Option 01 – Without ESP : Where the oxidant injection is after the hood in absence of ESP in Exhaust duct.