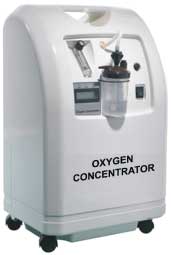

Air enters in medical oxygen concentrator through cabinet air

intake filter. This filtered air enters the compressor via a suction

resonator and fine filter, which quiets the suction sounds made by

the compressor. Pressurized air then exits the compressor and

passes through a heat exchanger, which reduces the temperature

of the compressed air. Next, an electronic valve (control valve)

system directs the air into one of two sieve beds that contain

molecular sieve. The special characteristic property of molecular

sieve is that it physically attracts (adsorbs) nitrogen when air

passes through this material, thus enabling the separation & production of high purity oxygen.

Air enters in medical oxygen concentrator through cabinet air

intake filter. This filtered air enters the compressor via a suction

resonator and fine filter, which quiets the suction sounds made by

the compressor. Pressurized air then exits the compressor and

passes through a heat exchanger, which reduces the temperature

of the compressed air. Next, an electronic valve (control valve)

system directs the air into one of two sieve beds that contain

molecular sieve. The special characteristic property of molecular

sieve is that it physically attracts (adsorbs) nitrogen when air

passes through this material, thus enabling the separation & production of high purity oxygen.

There are two sieve beds or adsorbent columns; while one produces high purity oxygen (sieve1), the other (sieve 2) is purged of the nitrogen it adsorbed (collected) while it was producing oxygen. Each column produces oxygen for approximately 5.5 seconds and delivers it to the product storage volume in the end of the column. Oxygen exits the adsorbent column through a pressure regulator, flow control valve, flow meter, and final product filter. The flow control valve, which is part of the flow meter, controls the flow rate of oxygen delivered to the ozonator. The medical oxygen generator unit delivers up to 93% - 88% oxygen concentration at flow rates from 2 to 5 l/min. The remaining constituents of the product gas stream are nitrogen and argon, both of which are part of the air which are exhausted out from the system.